What we all need are a couple of these at 42.8% conversion efficiency!

July 30, 2007

From 40.7 to 42.8 % Solar Cell Efficiency

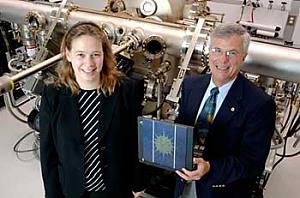

University of Delaware-led team sets solar cell record, joins DuPont on $100 million project.

Newark, Delaware [RenewableEnergyAccess.com]

Using a novel technology that adds multiple innovations to a very high-performance crystalline silicon solar cell platform, a consortium led by the University of Delaware (UD) has achieved a record-breaking combined solar cell efficiency of 42.8 percent. The current record of 40.7 percent was attained in December 2006 by Boeing's Spectrolab, Inc.

"The percentage is a record under any circumstance, but it's particularly noteworthy because it's at low concentration, approximately 20 times magnification. The low profile and lack of moving parts translates into portability, which means these devices easily could go on a laptop computer or a rooftop."

-- Allen Barnett, UD professor of electrical and computer engineering

The research was led by Allen Barnett, principal investigator and UD professor of electrical and computer engineering, and Christiana Honsberg, co-principal investigator and associate professor of electrical and computer engineering. The two direct the University's High Performance Solar Power Program and have been working to achieve the 50 percent efficiency goal set by the Defense Advanced Research Projects Agency (DARPA).

Barnett and Honsberg said that reaching the 42.8 percent mark is a significant advance in solar cell efficiency, particularly given the unique small and portable architecture being used by the consortium and the short time—21 months—in which it was developed.

Honsberg said the previous best of 40.7 percent efficiency was achieved with a high concentration device that requires sophisticated tracking optics and features a concentrating lens the size of a table and more than 30 centimeters, or about 1 foot, thick. The UD consortium's devices are potentially far thinner at less than 1 centimeter.

"This is a major step toward our goal of 50 percent efficiency," Barnett said. "The percentage is a record under any circumstance, but it's particularly noteworthy because it's at low concentration, approximately 20 times magnification. The low profile and lack of moving parts translates into portability, which means these devices easily could go on a laptop computer or a rooftop."

Honsberg said the advance of 2 percentage points is noteworthy in a field where gains of 0.2 percent are the norm and gains of 1 percent are seen as significant breakthroughs.

"This achievement is the direct result of the new architecture we developed under the DARPA program," Barnett and Honsberg said. "By integrating the optical design with the solar cell design, we have entered previously unoccupied design space leading to a new paradigm about how to make solar cells, how to use them, and what they can do."

In November 2005, the UD-led consortium received approximately $13 million in funding for the initial phases of the DARPA Very High Efficiency Solar Cell (VHESC) program to develop affordable portable solar cell battery chargers.

The highly efficient VHESC solar cell uses a novel lateral optical concentrating system that splits solar light into three different energy bins of high, medium and low, and directs them onto cells of various light sensitive materials to cover the solar spectrum. The system delivers variable concentrations to the different solar cell elements. The concentrator is stationary with a wide acceptance angle optical system that captures large amounts of light and eliminates the need for complicated tracking devices.

The VHESC would have immediate application in the high-technology military, which increasingly relies upon a variety of electronics for individual soldiers and the equipment that supports them. As well, it is hoped the solar cells will have a large number of commercial applications.

Today, the American soldier carries a pack that weighs nearly 100 pounds of which about 20 pounds are the three-day supply of batteries needed to power their gear. The DARPA program aims to dramatically reduce the battery logistics pipeline and provide the soldier with more power at reduced weight, thus improving mobility, survivability and the availability of advanced electronic technologies on the battlefield.

As a result of the consortium's technical performance, DARPA is initiating the next phase of the program by funding the newly formed DuPont-University of Delaware VHESC Consortium to transition the lab-scale work to an engineering and manufacturing prototype model. This three-year effort could be worth as much as $100 million, including industry cost-share.

During the first 21 months of the VHESC program, a diverse team of academia, government lab and industrial partners, led by UD, was focused on developing the technology basis for a new extremely high efficiency solar cell. The rapid success of that effort has enabled the present transition to a focus on prototype product development.

Barnett credits the early success of the program to the team approach taken to solving the problem. Partners in the initial phase included BP Solar, Blue Square Energy, Energy Focus, Emcore and SAIC. Key research contributors included the University of Delaware, National Renewable Energy Laboratory, Georgia Institute of Technology, Purdue University, University of Rochester, Massachusetts Institute of Technology, University of California Santa Barbara, Optical Research Associates and the Australian National University.

"What we've done," he said, "is create a virtual lab by having all of these companies, universities and national laboratories in the consortium. This has given us access to a broad range of capabilities in terms of expertise and equipment."

That approach is exemplified by the fact that the record-breaking system features three types of solar cells-one made by industry (Emcore), one by the National Renewable Energy Laboratory and one by UD.

"This is a solar cell that works," Barnett said, adding, "This technology has the potential to change the way electricity is generated throughout the world."

Barnett believes the 50 percent efficiency mark is just the beginning. "Our best inventions are in front of us," he said. "The consortium has been a super team, and has worked to develop new devices and architectures based on a breakthrough design paradigm."

The newly formed DuPont-University of Delaware VHESC consortium will be made up of industrial partners, national laboratories and universities. The consortium's goal is to create solar cells that operate at 50 percent in production, Barnett said. With the fresh funding and cooperative efforts of the DuPont-UD consortium, he said it is expected new high efficiency solar cells could be in production by 2010.

Linear Mode

Linear Mode