|

09-03-2007, 05:11 PM

09-03-2007, 05:11 PM

|

#1

|

|

Moderator

Join Date: Jun 2007

Home Port: Washington DC

Vessel Name: SV Mahdee

Posts: 3,236

|

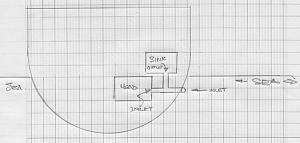

Our cruising boat had (past tense) a large number of thru-hulls. Besides the ones that must stay (like raw water for engine) we're trying to severely limit the number of thru-hulls we'll have as we refit the boat.

Originally, there was a thru-hull for direct dischanrge of each of the 2 heads, there were 4 foredeck scupper drains that connected with tubes down to thru-hulls below the waterline (I guess they didn't want to see dirt streaks from the scuppers on the boat sides...). There were two for the cockpit drains, one for a secondary galley pump (salt water in) one for the galley drain. One for engine raw water, And, 4 more that had been closed off because of various re-fits in the past.

We can live with dirt streaks from the scuppers, so we'll nix the 4 below waterline penetrations (without shut-off valves!) for those. We're more-or-less stuck with the saltwater intake thru-hull for the engine and for a saltwater wash-down pump as well as main head supply (assume only one large thru-hull for this, not two or more). Getting rid of another thru-hull, we're planning on the second head not having a standard marine toilet at all, but instead it will be having one of the many options that are either composting, incinerating, or port-a-potty like in nature. The only reason for it to have a toilet at all is the "what if something happens" to the main toilet.

We are considering complicating our lives (mechanically and power-consumption-wise) but reducing the number of below water thru-hulls by requiring galley and head drains to be pumped to above waterline thru-hulls (holding tank for head that would be evacuated via pumpout with no direct discharge option). This would allow us to live with less in the way of thru-hulls for "plumbing". What are your thoughts on this issue? Am I being too paranoid about number of thru-hulls and should just go-ahead and have them where needed? Clearly, some folks just have single large thru-hull for saltwater intake and manifold off it, but I'm talking more about drains here (from galley, two head sinks and shower).

We already are considering enough in the way of "extra" holes in the boat with an FLS which requires 2 penetrations...I just keep thinking of any way to reduce hull penetrations below the waterline....

|

|

|

09-03-2007, 06:23 PM

09-03-2007, 06:23 PM

|

#2

|

|

Admiral

Join Date: Sep 2005

Posts: 1,619

|

I agree fully with you. I am paranoid regarding through hulls and have never understood the leisure sailing market's perchant for putting unnecessary holes in vessels.

It is standard practise here in Scandinavia on ships and boats used commercially to have a sea water intake on each side of the hull connected through a manifold to the raw water users. Discharges are, as far as possible, above the water line. We also, as far as possible in small vessels, arrange the pipework so that pumps such as the toilet pump, deck wash pump, engine cooling water pump etc. have double functions so that, in an emergency, they can also be used as bilge pumps.

I am in the process of converting the Swiss cheese of NAUSIKAA's hull to an almost holeless unit. I have "patched up" one hole; two more to go this winter. I have also replaced ALL through hulls which were of the inferior gate valve type to bronze ball valves.

I think the basic premise of seaworthiness is to keep the sea out of the boat and the crew in it!

Aye // Stephen

__________________

|

|

|

09-03-2007, 10:06 PM

09-03-2007, 10:06 PM

|

#3

|

|

Admiral

Join Date: Jan 2005

Home Port: Darwin

Vessel Name: Sandettie

Posts: 1,917

|

I agree that limiting the number of through hull fittings is good sense. However, manifolding comes with its own problems which are probably little different in character. Manifolding generally requires more plumbing which takes more space, adds more bends which can lead to blockages (especially at unavoidable 90 degree bends), and there are just as many holes for water to enter if something goes wrong. 5 holes are still 5 holes which need to be clamped, irrespective of whether they are directly in the hull, or indirectly in the hull through a manifold. Extra plumbing means chafe protection becomes critical.

Theoretically a manifolded intake (or outlet) must be larger to allow for the use of more than one appliance at any one time. This prompts two questions: Is one big hole better than several small ones? Is manifolding outlets hygenically safe where toilet waste is involved?

In over 30 years of boating, I have never had a through hull fitting fail. But I have had stainless clamps fail on fitting's tails. Whether manifolded or not, plumbing will still require at least the same number of clamps...perhaps more. Noticing a clamp of 100mm diameter missing from a cockpit drain can cause the adrenaline to flow very smartly. Checking 28 below water line clamps (many on engine cooling/refrigeration and hot water heat transfer) is now written into the boat's maintenance schedule right beside 'soft wooden bungs/mallet'.

Interestingly, the one 'hole' which is of major concern is where the prop shaft exits the stern tube. The dripless 'submarine' seal has unnacountably let in enough water to cause my heart to thump twice in the past 5 years. A quick smear of grease and venting an air lock has fixed the problem....But when it occurs, it is a real bar-steward!

I have 8 through hull fittings including the tail shaft, sounder and cockpit drains.

David

__________________

" if at first you don't succeed....Redefine success"!

|

|

|

09-04-2007, 04:35 AM

09-04-2007, 04:35 AM

|

#4

|

|

Admiral

Join Date: Sep 2005

Posts: 1,619

|

What you say about manifolding is very true David.

I should, in all honesty, point out that one of the main reasons for having just a few through hulls is that they are also fitted with compressed air blow-back systems in order to blow out brash ice which enters and blocks the intake.

As rightly pointed out, the main issue is the fitting and maintenence of through hulls of good quality.

On the subject of holes in the hull, has anyone any experience of echo-sounder and log fittings failing?

Aye // Stephen

|

|

|

09-07-2007, 03:59 AM

09-07-2007, 03:59 AM

|

#5

|

|

Ensign

Join Date: Sep 2007

Posts: 9

|

LESS HOLES, thanks!

I have worked for over 5 months to rebuild my Cheoy Lee. It is quite old, and the hull is made of fiberglass. While supposedly built to Lloyd's standards, and supposedly a top quality "early" (read: extra thick) hull... I encountered some shocking problems while working on her, on the hard... And the main one problem arose one day, while I was examining the bottom of the hull, standing beside the boat on the ground. The old depth sounder sensor was mounted beneath a balsa protector, which appeared to be "glued" onto the boat with caulking. I simply gripped it, and with very little effort, pulled the thing off the hull! What a shock.  Beneath the protector lay a LARGE 3/4-inch hole, which was drilled to permit a tiny wire cable to protrude through the bottom; while there was a layer of black caulking over the hole, it was no more than a 1/8 of an inch thick! One log or even a big fish could have easily dislodged the depth sounder protector and sprung me a major leak... Luckily, the hole was easily accessed beneath one of the berths inside the cabin. I simply ground out all the caulking, down to some fresh fiberglass and put in several layers of fiberglass, using the correct top-grade expoxy. I reinforced the blip enough to guarantee that there would be no chance for a quick fountain to sprout in the bottom of my cabin. Wow.

There are at least five or six other big thru-holes. Two are for the toilet. I replaced the old toilet with a new one. But the more I think about it, and ponder the possibility that the wood below the fiberglass shell that comprises each through-hull along with the brass fitting is simply rotten pulp, it seems to appear more sensible to dig-out the old through-hulls and put a porta-potty into the head...

At the back of the boat are two through-hulls just below the water line that are connected to the cockpit drains, the principle being to generate continuous suction to draw out cockpit water continuously whilst sailing... Of course it works like a charm, and the water sucks out quite rapidly. However, these through-hulls are also quite old, and I can see some evidence of wood decay beneath the fiberglass that covers each block and the brass component mounted in it... That wood may really be rotten, as it does not seem to be teak... So, I might just need to dig out the through-hulls and rebuild them as a final safety step to make my boat truly safe, and up-to-date and even more importantly, certifiably fit...

I do not like through-hulls... If I can, I will remove all of them up and smoothly seal the hull, except maybe for the cockpit drains.

Happy grinding!

__________________

Yea, foolish mortals, Noah's flood is not yet subsided; two thirds of the fair world it yet covers.

~ Melville

|

|

|

09-07-2007, 05:10 AM

09-07-2007, 05:10 AM

|

#6

|

|

Admiral

Join Date: Oct 2004

Posts: 3,067

|

By what has been discovered so far in the through-hull exploration - if the boat is still on the hard -

borrow a moisture meter and check the hull below the water line ( at 2ft intervals ---vertical and at 15" ---horizontal - then at each high level reading, mark the spot by writing in the result.

If unsure as to the interpretation of the results, take them to a specialist.

__________________

|

|

|

09-07-2007, 05:39 AM

09-07-2007, 05:39 AM

|

#7

|

|

Ensign

Join Date: Sep 2007

Posts: 9

|

Quote:

Originally Posted by MMNETSEA

- if the boat is still on the hard - borrow a moisture meter and check the hull below the water line ( at 2ft intervals ---vertical and at 15" ---horizontal - then at each high level reading, mark the spot by writing in the result.

If unsure as to the interpretation of the results, take them to a specialist.

|

Do you know, if the boat stays "too long" out of the water, if the fiberglass will suffer as a result? (I hope not.) It will have been sitting there out of the water for over two years by the time I put her back in the water next spring...

As far as i know, the boat is still on the hard. I plan to do some more grinding and refilling upon my return, as there are still a few little bubbles. I have already ground many out, but only partially refilled them. If feasible, I plan to give the whole thing a layer or two of fresh gelcoat, and maybe a coat of bright "coast-guard" yellow Awlgrip... I have already refinished the teak boards on top twice, and finally used the supposedly tougher "Cetol"... (I am curious to see how that stood up during the last couple of seasons I wasn't living there in Canada...)

__________________

Yea, foolish mortals, Noah's flood is not yet subsided; two thirds of the fair world it yet covers.

~ Melville

|

|

|

09-07-2007, 06:44 AM

09-07-2007, 06:44 AM

|

#8

|

|

Admiral

Join Date: Oct 2004

Posts: 3,067

|

Quote:

Originally Posted by Popo

Do you know, if the boat stays "too long" out of the water, if the fiberglass will suffer as a result? (I hope not.) It will have been sitting there out of the water for over two years by the time I put her back in the water next spring...

As far as i know, the boat is still on the hard. I plan to give the whole thing a layer or two of fresh gelcoat,

|

" Do you know, if the boat stays "too long" out of the water, if the fiberglass will suffer as a result?"

It depends ! This is not meant to be a clever answer - as it really depends where the boat was being kept - eg in the sun ? In the rain - how much rain water got into the boat ? The hull 's paint , gelcoat and antifouling will deteriorate.

"As far as i know, the boat is still on the hard." If you have a means of checking , then also examine the gelcoat again - the idea of just adding a couple of coats needs to be researched :- have a look at this website ---

http://www.javelin38.com/GelCoat.html

__________________

|

|

|

09-07-2007, 12:10 PM

09-07-2007, 12:10 PM

|

#9

|

|

Moderator

Join Date: Jul 2007

Posts: 700

|

One unusual feature that my current boat has, that I haven't seen a lot of, is that there are no through-hull outlets for the sinks. They all lead to a t-junction in the water inlet for the heads. So every time you flush the heads you suck the water out of the sink outlets as well as any extra needed from the salt water inlet. It might't seem like much, but it saves a couple of through-hulls. I had my doubts about it at first but it seems like on an average day you use more water flushing the heads than you tip down the galley sink. There doesn't seem to be any additional scale or other build up in the plumbing as a result -- my guess would be that the alkalinity of the detergents/soaps/etc going down the sink are counteracted by the acidity of what gets flushed away in the heads.

|

|

|

09-08-2007, 07:33 AM

09-08-2007, 07:33 AM

|

#10

|

|

Admiral

Join Date: Oct 2004

Posts: 3,067

|

Quote:

Originally Posted by delatbabel

One unusual feature that my current boat has, that I haven't seen a lot of, is that there are no through-hull outlets for the sinks. They all lead to a t-junction in the water inlet for the heads. So every time you flush the heads you suck the water out of the sink outlets as well as any extra needed from the salt water inlet.

|

Hi Del,

Intrigued by your sinks' plumbing into the heads' salt water inlets (not the discharge outlet into the holding tank or out through the heads outlet through-hull)

Question ;- what happens when the boat is heeled over on the side where the head's through-hull inlet is located ?? ie . what is to stop salt water being pumped into the sink outlet ? Check valve ??

__________________

|

|

|

09-08-2007, 09:22 AM

09-08-2007, 09:22 AM

|

#11

|

|

Moderator

Join Date: Jul 2007

Posts: 700

|

Quote:

Originally Posted by MMNETSEA

Question ;- what happens when the boat is heeled over on the side where the head's through-hull inlet is located ?? ie . what is to stop salt water being pumped into the sink outlet ? Check valve ??

|

The heads are vacuum-flushed and have a valve on the inlet. That valve only allows water into the heads when the lid is closed and the vacuum pump is operated, hence there can be no chance of water being pumped into the sink from the heads.

To prevent seawater being pushed into the sink from heel pressure there is a seacock on that inlet of course which can be shut off, but recently we were beam reaching with most of a full mainsail and nearly a full genoa with about maximum heel, and the water level didn't come up much higher than the base of the sink in the heads -- because it's a hand washing sink rather than a galley sink or heads inlet, the level of the sink is quite high. So there was a little bit of water splashing up out of the bottom of the sink plughole into the sink, but not very much.

Of course as soon as you flush the heads, that water gets sucked out fairly quickly because it's then attached to the inlet side of the heads, which has vacuum pressure applied to it. You could in fact flush the heads with the inlet seacock shut off, and a sink full of water.

I've yet to need to shut that seacock at sea, however perhaps in stormy conditions it may have to be shut off when the heads aren't in use. When in potential knockdown conditions it'd be seamanlike to have all seacocks closed anyway.

Del

|

|

|

09-08-2007, 09:52 AM

09-08-2007, 09:52 AM

|

#12

|

|

Admiral

Join Date: Oct 2004

Posts: 3,067

|

Thanks Del,

Makes sense !!

I remember a few years ago delivering the yacht "Vadio" from Macao to Hong Kong in a very strong South Wester. At some point we noticed water slopping just above the floor boards - got the hand pumps going - suspected that the fresh water tank had sprung a leak. Kept on pumping - the water kept on coming - tasted the water = fresh ! Exhausted; slowed the boat down to even keel , presto the water slowed down - took off again and the water poured in. Check the sink =

water being syphoned in ! We were in waters being fed by the Pearl River , hence the taste = fresh water. Broke the syphon - pumped out the rest of the "fresh" water -- Broke open a couple of bottles of Portuguese "Casal Garcia" and thanked Neptune for our deliverence!

Richard

__________________

__________________

|

|

|

|

|

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

Recent Threads

Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Linear Mode

Linear Mode